A warehouse control system (WCS) is a computer software application that sends responsibilities to systems in the warehouse. It tells how to move items and orders from receiving to delivery. A WCS makes sure everything happens in the proper order to make the warehouse more efficient.

The WCS sits below this; it provides real-time performance control of automated equipment such as transporters, sortation systems, AS/RS hoists, robots, and AGVs.

Table of Contents

What is a Warehouse Control System?

A Warehouse Control System is designed to:

- Monitor automated equipment in a warehouse.

- Control workflows such as picking, packing, sorting, and shipping.

- Optimize movement of goods and reduce manual errors.

- Improve productivity and reduce operational costs.

Unlike WMS, which focuses on inventory and planning, WCS focuses on execution and automation at the operational level.

Uses of (WCS)

Warehouse Control Systems are the middleware commonly between the WMS and the floor-level panels for the various “Keys of Mechanization.” These Islands of Mechanization include, but are not limited to:

Automatic Sortation

In-Motion Print and Apply

Pick/Put to Light

Carousels

In-motion Weighing

Voice Pick

Goods-to-person systems

Why warehouses need a WCS?

If your operation has any significant automation — conveyors, sortation, palletisers, AS/RS, or robots — you’ll quickly discover two truths:

- Machines need very precise, immediate instructions (millisecond decisions) to avoid collisions, deadlocks, or inefficient routing.

- High-level systems (like ERPs or WMS) are great at planning and inventory logic but usually aren’t built for millisecond control of hardware.

A WCS fills that gap: it translates the “what to do” from WMS/WES into “how and when to move” for physical equipment, and it continuously monitors equipment status and throughput in real time.

Day-to-day: what a WCS actually does

Here are the common live functions you’ll see in a WCS:

- Task routing — send a tote/pallet to the best available lane, sorter line, or packing station.

- Equipment control & safety — start/stop conveyors, manage diverters, interlock gates, and ensure safe robot movements.

- Load balancing & congestion avoidance — reroute items to prevent bottlenecks and keep throughput steady.

- Real-time exception handling — automatically handle jams, broken scanners, or blocked lanes and escalate where needed.

- Traffic sequencing — ensure that items arrive in the right order and time for packing or palletising.

- Data & telemetry — provide dashboards and live metrics (throughput, uptime, queue length, etc.) for supervisors.

What are the Benefits of Using a Warehouse Control System(WCS)?

A warehouse control system can help improve the complete workflow in the warehouse by coordinating labor and material flow activities. This direction can lead to more effective use of time and resources, which results in increased output.

| Benefit | Impact on Warehouse |

| Higher Throughput | Faster order processing |

| Reduced Downtime | Fewer conveyor jams |

| Lower Labor Costs | Less manual intervention |

| Better Accuracy | Fewer misrouted shipments |

| Improved Visibility | Real-time dashboards |

| Scalability | Easy automation expansion |

Historical Performance Data:

It is crucial to monitor and assess your warehouse systems’ working performance nonstop to provide your experts and service staff with clarity into when tackle care is needed. With this data at your fingertips, you can avoid unexpected interruptions or disruptions to your business.

Improved Visibility in Warehouse Control Systems

The WCS provides real-time one-to-one care, controlling, and diagnostics of computerized systems based on data from system-level controllers and devices, including real-time views of register levels, order status, picking progress, etc. This improved perceptibility can help to identify problems early on so that remedial success can be taken rapidly.

Increase in Productivity:

Increase the productivity of various material handling sub-systems such as AS/RS and transporter belts by organizing material handling systems to determine the most efficient product flow. In addition to that, the WCS can be used to optimize storage utilization, leading to reduced operative costs.

Key Functions of a Warehouse Control System

| Function | What It Does | Practical Example |

| Routing Control | Directs cartons, totes, or pallets | Sends package to correct shipping lane |

| Traffic Management | Prevents conveyor congestion | Diverts items when a lane is full |

| Equipment Monitoring | Tracks machine status | Detects jam on sorter belt |

| Task Sequencing | Controls order of movements | Ensures items arrive in packing sequence |

| Load Balancing | Distributes workload evenly | Balances cartons across multiple chutes |

| Exception Handling | Handles system errors automatically | Stops system if scanner fails |

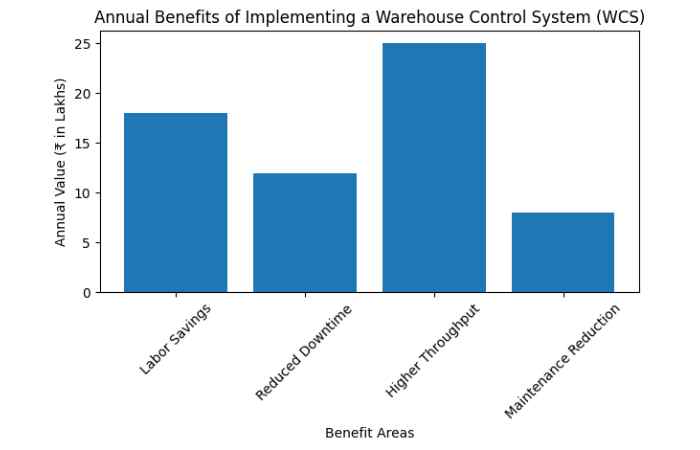

ROI Calculation Table

| Cost / Savings Area | Estimated Annual Value |

| Labor Savings | ₹18,00,000 |

| Reduced Downtime | ₹12,00,000 |

| Increased Throughput | ₹25,00,000 |

| Maintenance Reduction | ₹8,00,000 |

| Total Annual Benefit | ₹63,00,000 |

Advantages of Warehouse Control Systems

1. Improved Inventory System Picking Accuracy

Imprecisions in your inventory management can lead to low customer satisfaction, high product returns, and loss of revenue. By using it, you can implement processes to improve the correctness of your inventory buying by ensuring your stock levels are followed to avoid over or under-stocking your warehouse, record storage by tracking the locations of all items from put away, and picking and packing by rearrangement the process from office to warehouse.

2. Improved Customer Service

A positive customer experience will build brand faithfulness and customer satisfaction, so meeting or exceeding their expectations is significant. You may communicate with your customers automatically or input data, such as tracking numbers from one system to another, which could lead to missed or incorrect communications.

3. Reduced Stock Inventory Costs in WCS

To run an efficient storeroom, you want to have the proper stock levels at the right time, also known as stock control. It’s easy to think you must always have high stock levels. However, that can result in over-ordering and inefficient storage of goods that are not being well-ordered.

An advantage of using a WMS is tracking stock levels without undertaking timely stock receipts. If your WMS has reporting capabilities, you can also begin to see movements in orders and stock delivery time scales. This allows you to plan and confirm the correct stock levels, especially during your seasonal points, and avoid over or under-stocking – ultimately saving you money by reducing storage costs and increasing supply chain distinguishability.

4. Reduce Time Spent Managing in WCS

Without a centralized Warehouse Management System, you are likely spending a lot of your time managing everything around you, from accepting orders and stock deliveries to creating pick lists and instructing your warehouse staff.

This system can help reduce the amount of manual intervention needed day-to-day. Orders can be automatically accepted and assigned, and further automation within the system can set orders for picking. Additional functionality, such as a warehouse map, can also speed up stock delivery and put it away by clearly understanding where records should be placed.

5. Increase the Speed of Orders

Customers expect faster delivery from point-of-sale with 24 and 48-hour delivery options offered as standard from many retailers.

A Warehouse Management System can help speed up fulfillment processes by automating shipping label generation and prioritizing pick lists that go directly to the picker/packer work schedule via technology such as mobile barcode scanners.

Disadvantages of Warehouse control Systems (WCS)

1. Set-up Costs

The initial cost of a new system or software can be an investment. While it can seem like a risk and a significant expense, your time and money savings within your first year should offset some or all of your initial outlay.

2. Set-up in Warehouse control Systems (WCS)

Another part of applying a new system is setting it up manually. Your business will likely consist of multiple existing systems and will take some time to connect them to your new WMS system.

Essential business functions like your accounting software and marketplaces are crucial combinations to set up correctly. Additionally, your WMS can offer enhanced functionality, such as courier rules based on size or weight, to get the best consignment rates.

3. Data Maintenance

Once your data sources, integrations, and systems are all linked to your Warehouse Management System, the data management task is unfortunately not completely automatic. You will likely still need to ensure your data is transferring correctly and that all combinations remain connected. While this will not be a daily task, it will take some time out of a month.

4. Potential Single Point of Failure

Many businesses we speak to are concerned that combining all of your systems into one Warehouse Management System gives you a single point of failure for your entire warehouse operations. This is a legitimate concern and could result in no access to data if the system goes down, halting all of your activity.

While this is a possibility, an essential thing to consider if this is a concern is the reliability of the WMS you choose alongside the access to support the WMS provides to get you back up and running as soon as possible.

Difference Between Warehouse Control System (WCS) and Warehouse Management System (WMS)

Both Warehouse Control System (WCS) and Warehouse Management System (WMS) are important in modern logistics and supply chains. Companies such as Amazon, DHL, and Flipkart use both systems together to manage large and automated warehouses efficiently.

Below is a clear comparison in table form:

| Feature | Warehouse Control System (WCS) | Warehouse Management System (WMS) |

| Definition | A system that controls and manages automated warehouse equipment in real time. | A software system that manages inventory, warehouse operations, and order planning. |

| Focus Area | Automation and execution of tasks. | Inventory tracking, storage, and planning. |

| Main Purpose | Controls conveyors, robotics, sorters, and automated machines. | Tracks stock levels, locations, and warehouse workflows. |

| Level of Operation | Operational level (execution). | Strategic and tactical level. |

| Real-Time Control | Yes, provides real-time control of machines. | Limited real-time control. |

| Inventory Management | Does not directly manage inventory. | Manages inventory and stock accuracy. |

| Equipment Control | Directly controls material handling equipment. | No direct control of equipment. |

| Order Management | Executes order movement and routing. | Plans and organizes order processing. |

| Integration | Works with WMS and ERP systems. | Integrates with ERP, supply chain, and transport systems. |

| Decision Making | Focuses on automation and routing decisions. | Focuses on inventory and warehouse planning decisions. |

| Data Handling | Collects real-time equipment and performance data. | Manages product, order, and inventory data. |

| Examples of Tasks | Conveyor control, robotic picking, automated sorting. | Stock tracking, space optimization, order allocation. |

| Users | Automation engineers and operations teams. | Warehouse managers and supply chain planners. |

| Technology Used | Robotics, IoT, automation software. | Cloud, analytics, inventory software. |

| Role in E-commerce | Speeds up automated order fulfillment. | Ensures correct inventory and stock visibility. |

Future Trends in Warehouse Control System (WCS)

Warehouse Control Systems (WCS) are evolving rapidly due to automation, AI, and digital transformation. Global logistics companies such as Amazon, DHL, and FedEx are investing heavily in advanced WCS to improve speed, accuracy, and efficiency in modern warehouses.

1. Artificial Intelligence (AI) and Machine Learning Integration

AI and machine learning will become core features of future WCS. These technologies help in predictive decision-making, optimizing picking routes, forecasting demand, and reducing errors.

- Predictive order processing

- Smart inventory movement

- Real-time optimization

- Self-learning automation systems

AI-driven automation is expected to become an operational necessity in warehousing.

2. Autonomous Mobile Robots (AMRs) and Robotics

Future WCS platforms will coordinate fleets of robots and automated equipment.

Key developments:

- AMRs replacing traditional automated guided vehicles

- Intelligent picking and sorting robots

- 24/7 automated operations

- Reduced labor dependency

AMRs are projected to dominate new warehouse automation deployments by 2026.

3. IoT and Real-Time Data Connectivity

WCS will use Internet of Things (IoT) sensors to connect devices and equipment.

Benefits:

- Real-time tracking of goods and machines

- Predictive maintenance

- Better workflow visibility

- Improved performance monitoring

IoT-enabled devices provide insights that help optimize warehouse efficiency and decision-making.

4. Cloud-Based and Scalable WCS

Cloud computing will make WCS more flexible and scalable.

Future systems will offer:

- Remote monitoring and control

- Multi-warehouse coordination

- Faster system upgrades

- Integration with ERP and WMS platforms

Cloud platforms support real-time data processing and global accessibility.

5. Real-Time Orchestration and Intelligent Decision Systems

WCS will evolve from simple equipment control to intelligent orchestration.

Key changes:

- Dynamic task allocation

- Predictive bottleneck management

- End-to-end automation

- Integration with Warehouse Execution Systems (WES)

Future systems will predict congestion and adjust operations automatically.

6. Human–Machine Collaboration

Instead of replacing workers, WCS will support collaboration between humans and robots.

Examples:

- Voice picking

- Wearables and AR support

- Cobots working with employees

- Reduced physical strain

Automation will enhance productivity and job satisfaction.

7. Sustainability and Green Warehousing

Environmental sustainability will shape WCS design.

Focus areas:

- Energy-efficient robotics

- Reduced carbon footprint

- Optimized transport routes

- Eco-friendly warehouse layouts

Automation reduces travel distance and energy consumption.

8. Modular and Flexible Automation

Future warehouses will adopt modular and plug-and-play automation.

This includes:

- Flexible robotic systems

- Scalable automation layers

- Adaptive layouts

- Dynamic storage solutions

Companies will adopt phased automation rather than full automation.

9. Cybersecurity and Data Protection

As warehouses become digital, security will be critical.

Future WCS will include:

- Advanced cybersecurity tools

- AI-driven threat detection

- Secure cloud and IoT systems

- Data privacy compliance

Cyber risks are increasing with digital warehouse transformation.

10. Advanced Algorithms and Smart Scheduling

Traditional rule-based scheduling will be replaced by advanced algorithms.

Innovations:

- Strategy-based decision models

- Reinforcement learning

- Digital twins

- Predictive analytics

Future WCS will focus on data-driven real-time execution.

Top Global Warehouse Control System Vendors

Warehouse Control System vendors provide automation, robotics control, real-time monitoring, and equipment coordination for modern warehouses. These vendors help companies improve efficiency, speed, and accuracy in supply chain operations.

| Country | Vendor | Key Solutions & Focus Areas |

| USA | Honeywell Intelligrated | Automation, robotics, WCS, conveyor & sorting |

| USA | Manhattan Associates | Cloud WCS, supply chain, AI-driven execution |

| USA | Oracle Corporation | Integrated WCS, ERP, and supply chain |

| USA | OPEX Corporation | Robotics, automated picking, fulfillment |

| USA | Bastian Solutions | End-to-end automation and WCS |

| Germany | Dematic | Robotics, WCS, warehouse execution |

| Germany | SSI Schaefer | Automated storage, WCS, logistics software |

| Germany | KION Group | Automation, supply chain and intralogistics |

| Germany | Jungheinrich | Automation and warehouse control |

| Switzerland | Swisslog | Robotics, AI, WCS, healthcare logistics |

| Japan | Daifuku Co., Ltd. | Automated warehouses, WCS, robotics |

| Japan | Murata Machinery | Automated storage, control systems |

| Netherlands | Vanderlande | Sorting, baggage, e-commerce fulfillment |

| Austria | KNAPP AG | Robotics, warehouse control, e-commerce |

| Austria | TGW Logistics Group | Warehouse automation, WCS software |

| Spain | ULMA Handling Systems | AS/RS, WCS, robotics |

| France | Fives Group | Smart warehouse control |

| Italy | System Logistics | Integrated logistics and WCS |

| India | GreyOrange | AI robotics, WCS, AMR solutions |

| India | Addverb Technologies | Autonomous robots, warehouse control |

| China | Geek+ | AMR robots and intelligent WCS |

| China | Hikrobot | Vision-based robotics and warehouse systems |

Final Words

WCS is not magic, but it’s often the most practical way to make automation predictable, safe, and productive. If your warehouse is still using manual switchovers, “tribal knowledge” ladder logic, or repetitive manual lane balancing during peaks, a WCS will likely pay for itself in reduced labor and increased throughput.